Laser cutting technology has gained much popularity over the years. It is ideal for creating intricate designs and patterns on fabric, wood, and metal. Laser cutting is the best choice for many projects to produce accurate, precise cuts. However, if you’re looking to start up a project, there are things you need to know.

What is a laser cutting machine?

Before starting your project, you should learn more about laser cutting machines. The machine is one of the most widely used metals for cutting metals and other materials in different industries.

It is a device that uses a laser beam to cut materials. It is directed using laser optics and Computer numerical control (CNC) technology. You can use it for cutting, engraving, and marking.

How does a laser cutter work?

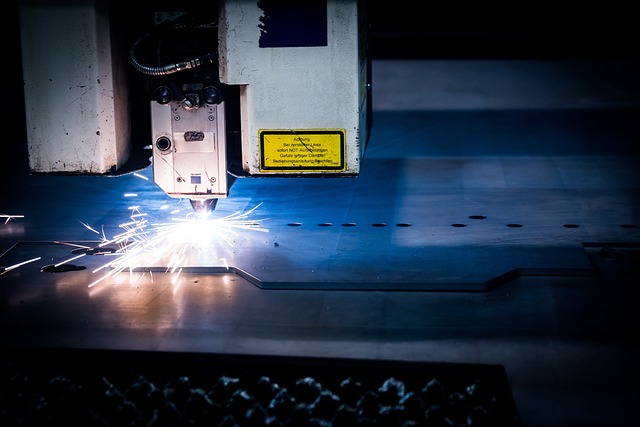

Laser cutting is achieved by applying high-power density energy from laser focusing. Through computer controls, the laser is discharged through pulses, outputting a controlled repetitive high-frequency pulsed laser that forms a beam. The beam is guided, reflected by the optical path, and focused using a focusing lens.

A high-energy-density light spot is formed on the surface of the processed material. Once there is a spot, the laser cuts through, leaving a clean and precise cut.

What materials can be cut using laser?

A laser cutting machine is highly versatile. You can use it to cut through various materials, such as ceramics. However, a laser cutting machine is a great choice for cutting through;

- Stainless steel

- Steel

- Aluminum

- Nickel

- Brass

- Copper

Unfortunately, some materials should not be cut using a laser. That’s because the process will create toxic gases or dust that may damage the machine. The materials include

- Polyvinyl chloride (PVC)

- Polyvinyl butyrate (PVB)

- Beryllium oxide

- Carbon fibers

- Leather and artificial leather that contains chromium

What are the different types of lasers?

- Gas lasers: it is the oldest, and it uses carbon dioxide mixed laser. It is well suited for cutting through non-metals or engraving metals.

- Crystal lasers: The technique uses crystal mediums to allow for high-powered metal cutting abilities, allowing the processing of metal and non-metallic materials. However, they are more expensive and have the shortest lifespan.

- Fiber laser: Fiber lasers are the newest method, producing stronger, more focused beams through fiber optics. It is ideal for cutting heavier metal materials and saves production costs.

Benefits of laser cutting

Various industries continue to benefit from laser cutting. Its precise and accurate cut is the top benefit to manufacturers. They use it to create parts for other industries like automotive, aerospace, semiconductors, electronics, etc.

Another advantage is laser cutting is a non-contact process. Meaning the beam won’t touch the material being cut. These minimize damage to the material’s work surface and allow high-quality cuts. Also, laser cutting has the advantage of fast cutting speed, narrow gap, small heat-affected zone, and less material consumption compared to other methods.

Conclusion

Starting a laser cutting project is very beneficial. The technique offers excellent benefits that help cut production costs while getting the cleanest and most precise cuts. However, you need to be conversant with the above information about laser cutting before you start your project for optimum results.